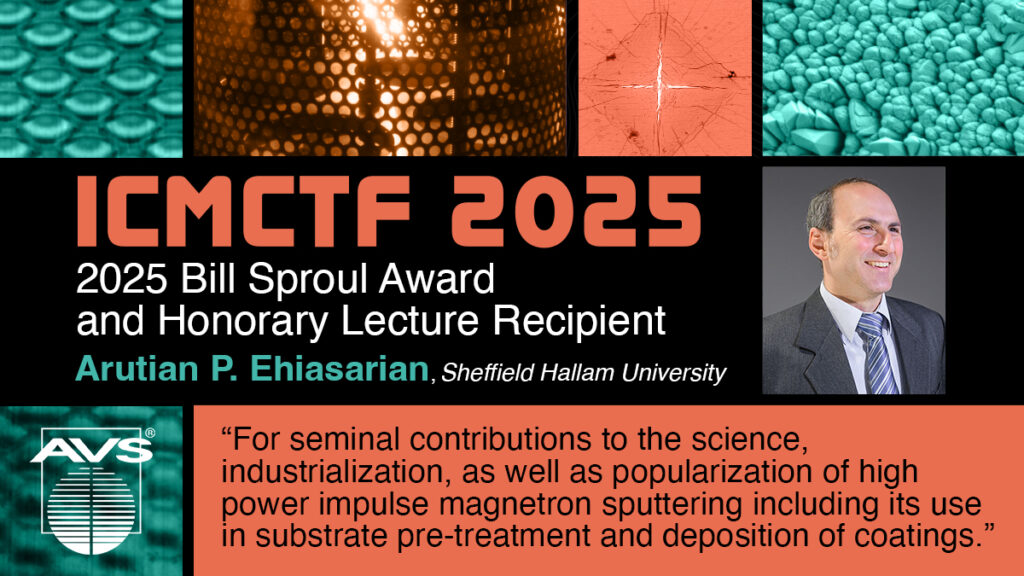

Purpose

The Bill Sproul Award and Honorary ICMCTF lectureship is to recognize the achievements of a mid-career researcher who has made outstanding scientific and/or technological contributions in areas of interest to the Advanced Surface Engineering Division (ASED) of the AVS, with an emphasis in the fields of surface engineering, thin films, and related topics.

Biography

Arutiun P. Ehiasarian is the Head of the National HIPIMS Technology Centre – UK and Director of the Joint SHU-Fraunhofer IST HIPIMS Research Centre opened in 2010. He has been part of the Nanotechnology Centre for PVD Research at Sheffield Hallam University since 1998. Arutiun is one of the pioneers of high-power impulse magnetron sputtering (HIPIMS) technology and has experience with cathodic arc evaporation and inductively coupled plasma-enhanced magnetron sputtering, as well as a range of plasma diagnostics and film characterisation techniques. His research concentrates on the development of plasma PVD technologies to improve the performance of coatings used for wear, oxidation and corrosion protection in automotive, aerospace and orthopaedic industries, as well as through-silicon via metallisation for semiconductor wafer processing, thin film photovoltaics, cryogenic materials for space satellites and superconducting thin films for particle accelerator cavities. He is an author of more than 200 publications, 9 patents and 1 book chapter in the field of PVD and HIPIMS. Arutiun is the Chair of the International Conference on HIPIMS organized jointly by Sheffield Hallam University and Fraunhofer IST, and a Fellow of the AVS and the Institute of Physics. His work in the field has been acknowledged with the R.F. Bunshah Award (2002), the TecVac Prize (2002), Hüttinger Industrial Accolade (2008), Peter Mark Award (2010), the Society of Vacuum Coaters Mentor Award (2012), Ionbond prize (2014) and Oike Award of Recognition (2018), European Physical Society Plasma Innovation Prize (2019) and the Surface Engineering Association Award (2023).